You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSafety & Efficiency

Glencore Nickel: A vision of Safety and Precision

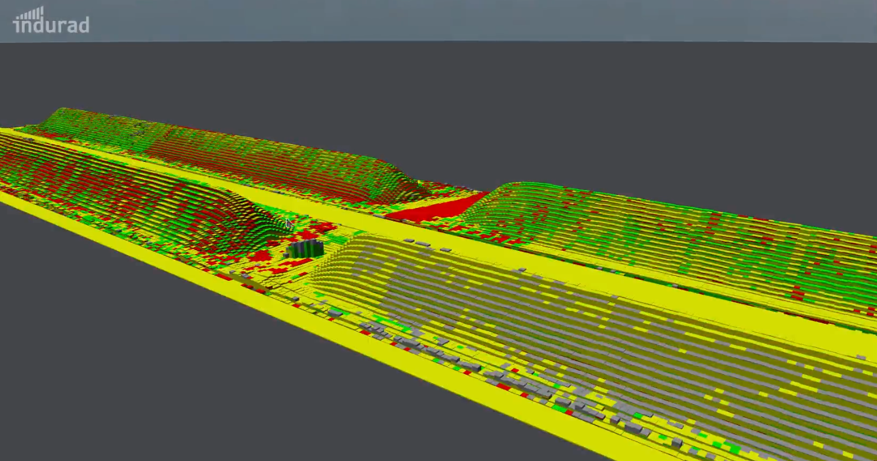

A dust suppression system impaires visitoin of the human operator unloading vessels at at Port of Quebec. Indurad “restores” the operator’s vision using it’s 3D radar technology.