2D & 3D VAULT SCAN

Norway Orepass

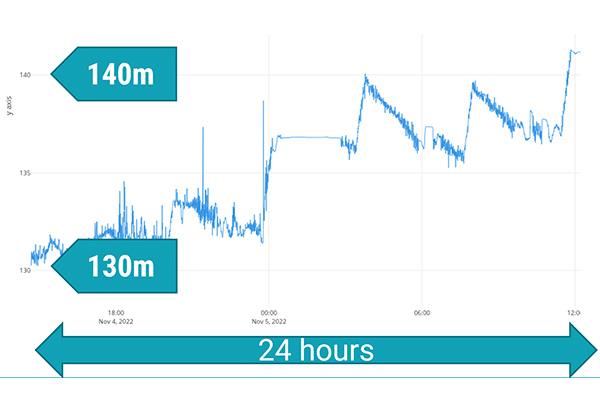

A 1D iLDR-H radar sensor under a primary crusher measures the level of a 200 meter long ore pass in an iron ore mine in Norway. The system shows the continuous changes in the level, allowing the customer to control the crushing and conveying.

In addition, the information on ore pass volume and changes in the ore pass allows informed decisions to be made to ensure that the ore pass is not worn or blocked.

Lime Producer

Fast and easy installation

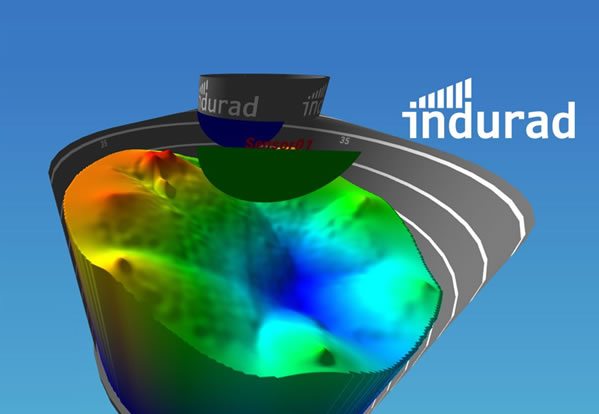

The compact iSilo solution, consisting of a single scanning radar (iSDR-P) and a combined processing and connectivity unit (iRPU-F) provides a complete surface model of the inventory.

Knowing the capacity and deriving the current fill level significantly improves loading and unloading and truck dispatch. The results are significantly reduced cue times and more customer deliveries per day. Especially one factor improves the overall dispatch process, as a loading truck does not have to wait any more until a unloading truck finished his work. So the system now allows simultaneous loading and discharging of the silo.

Aluminum Plant

Inventory information & Safety

The customer is an aluminum plant in Iceland. The material (alumina) they receive to feed the operation must be dispatched well in advance as it is delivered by vessels from distant suppliers around the globe.

The alumina is received into a large silo from which material is drawn into the operation. To maximize production, the silo should be close to empty when a ship arrives so that the maximum sized shipment can be received without halting production. To achieve this, precise knowledge of the volume of material in the silos is critical to make the optimal dispatching decisions in a long lead-time environment.

The customer also faced operational challenges when unloading the vessel as there was no information that could be used to adjust the silo’s 17 filling points individually. The material loaded into the silo was sometimes very unevenly distributed. To correct uneven loading, the operators could only slow the loading process to allow the material to slide down to a more even distribution. When the operators were able to see this effect during ship unloading, they were able to adjust different groups of filling points to make the filling more even. This ultimately allowed the customer to reduce unplanned and costly berth times.

Cement plant

Clinker Silo Greece

At our client site at a cement plant in Greece, knowing the exact fill level 24/7 is key to enable the plant manager to take the right decisions. The clinker silo acts as storage and buffer area between kiln and mill.

Thus, knowing both free capacity and remaining stock is important for a smooth management of upstream and downstream production. With the indurad iSilo solution, the client has this information available at all times. In addition, current dead stock in the silo is finally visible and thus can be taken into account to calculate current available capacity and to take corrective measures like wall cleaning. The indurad radar solution manages to scan where other technologies fail: high temperatures beyond 100°C, dusty environment, and moisture from the material. The sensor requires no regular cleaning or recalibration.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Peace of Mind

A&U Energie in Belgium uses indurad inventory measurement

Peace of mind or install and forget are the things you want to archive when it comes to plant automation and process planning. This is what indurad delivers.

Learn how our customer A&U Energy archived this and how the installation process of the Indurad solution was done by the customer and did not cause any headaches.