You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationA Quantum Leap for Bulk Terminals

To improve port operations, EECV Rotterdam is using a combination of Indurad solutions.

Learn how the customer uses the solutions for individual benefits and how they are combined for a quantum leap in bulk terminal operations.

World’s largest bucket wheel excavator

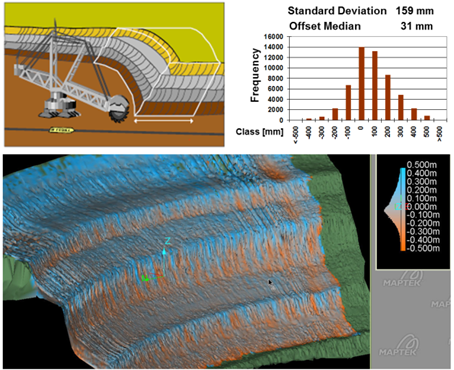

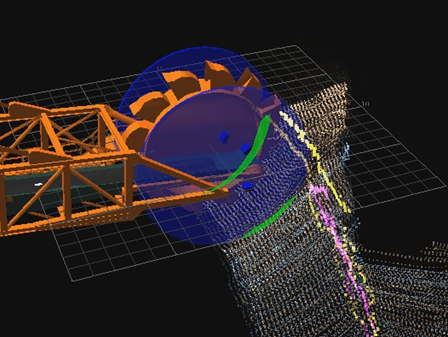

Automatic Block Cutting on Crawler Bucket Wheel Excavator: A multifunctional solution for the world’s largest bucket wheel excavator (240.000m³/day).

The indurad solution provides collision avoidance data and detects any object on either side of the bucket wheel.

At the same time, the system provides cutting depth control and thus increase the productivity of the machine.

indurad proved in a benchmarking field test – comparing indurad radar sensors against a leading industrial laser scanner – that, the standard deviation between radar and laser was only 0.03m, respectively. RWE considers the accuracy of indurad’s radars equal to that of laser sensors. RWE choose to install indurad because of the significantly higher availability offered by radar’s reliable performance under adverse conditions.

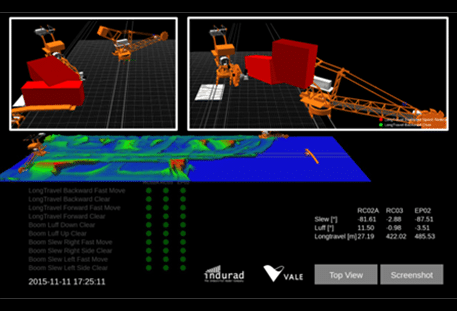

Full Yard Automation

INDURAD has delivered a complete yard automation project in at Vale’s main export terminal in Vitoria, Brazil including:

- GNSS

- 3D radar collision avoidance

- Rail & personnel detection

- Stockyard scanning for pile visualization.

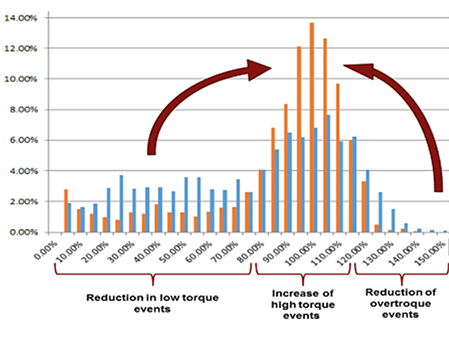

Production improvements

of Reclaimers and Loadout Station

indurad successfully delivered a customised turnkey project consisting of a Reclaimer & Loadout facility where the complete scoping, design, installation, control system integration, training and performance acceptance formed part of the scope. INDURAD delivered on the following requirements from the client:

- reduction of over torque events (-75%)

- increase of high torque reclaiming (+4,3%)

- elimination of air-digging

- reduction of attack-times

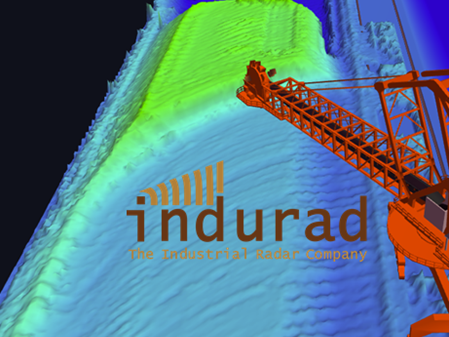

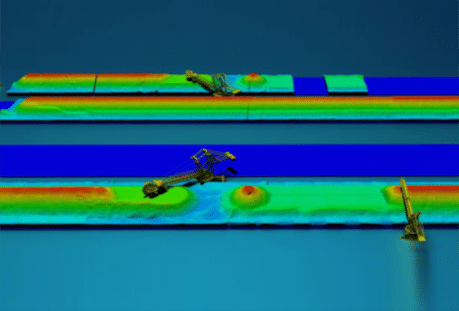

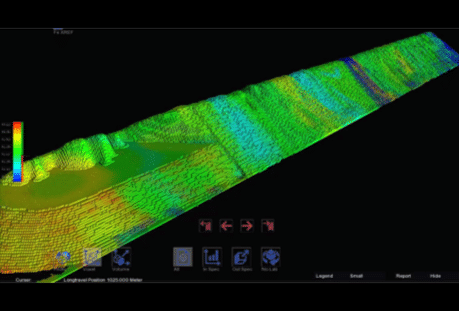

3D Stockpile with 4D Quality Tracking

At Assmang Iron Ore, South Africa indurad has delivered a complete Stacker/Reclaimer 3D stockpile solution with 4D quality tracking.

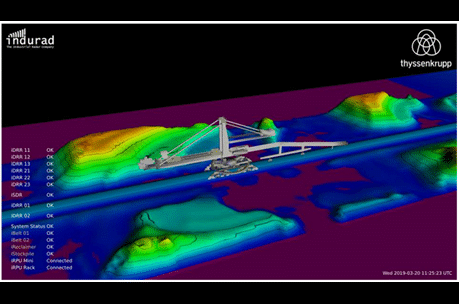

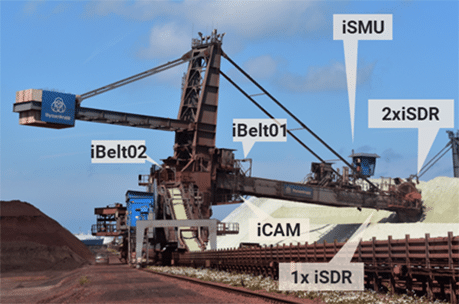

Full SR Automation at EECV – Rotterdam, Netherlands

INDURAD has achieved full automation of the stacker/reclaimer L3 and conveyor belts for a 24/7 operation, with the following integration solutions:

· iReclaimer – Cutting Assistance

· iStacker – Stacking Assistance

· iStockpile – Stockpile Management

· iBelt

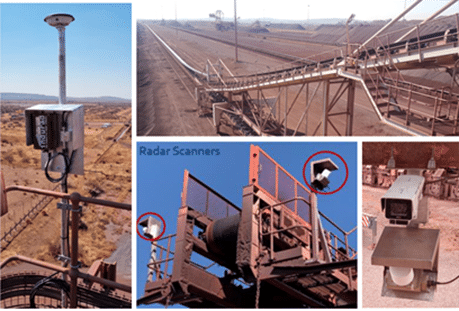

Productivity solution at Rio Tinto Gudai Darri

Indurad has devlivered the stockpile scanning and productivity solution at RioTinto´s flagship mine “Gudai Darri” (Koodaideri). It includes 2 Stackers and 1 Reclaimer. The order was given by FLSmidth to indurad with involvement of our Australian system integrators Intellect Systems and Paradigm.