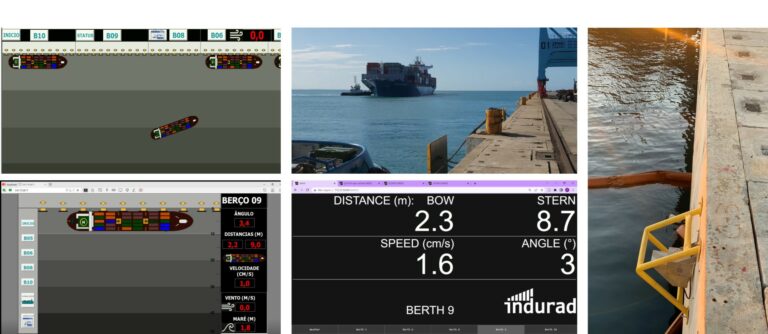

Port in Brazil

A port in Brazil uses the iBerth solution to be integrated with their harbour management system. Indurad provides data:

- distance of Bow

- distance of stern

- speed

- approach angle

In combination with further datapoints such as:

- vessel type and loading

- wind speed

- tide

the system provides a full set of information to the operators, increasing efficiency and safety in daily operations as well as in special conditions where operations are more difficult to perform (e.g. high tide, low tide, strong rain and thunderstorms etc.)

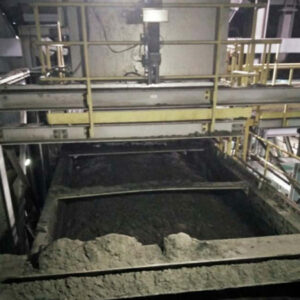

System upgrade from Laser to Radar

Performance deficits and constant cleaning efforts were the main drivers in 2012 to turn to Out Indurad for an update of the existing loading automation.

Particularly fast changing material properties (mostly driven by wet/dry material) as well as residual material were, besides the rainy environment, the main challenges.

indurad replaced the existing system based on PE cells and 2D laser sensors with a pure radar approach. The results exceeded all expectations. The customer reported:

- Increase of the capacity of the car rail up to 3 tons

- Increased homogeneity of load distribution on each wagon.

- Increased rail availability

- Increased operational safety.

A major consulting firm involved in this project reported an annual value contribution of $50 million.

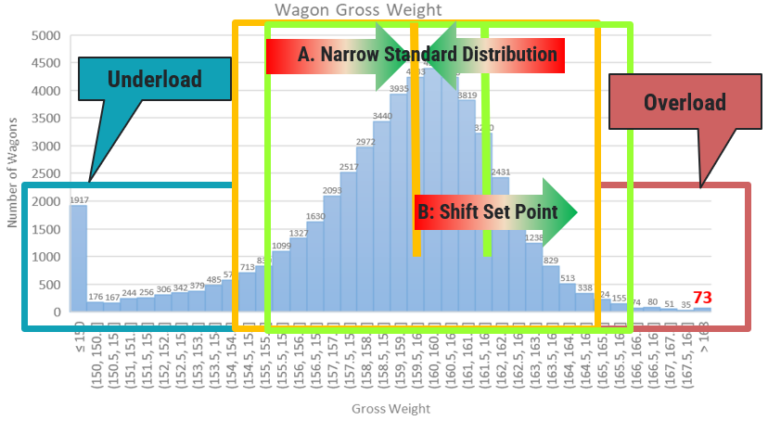

Performance Improvements Iron Ore Loadout

In this project for a major Australian iron ore mine in the Pilbara region, Indurad implemented a reclaimer and loadout solution as a turnkey supplier.

The main objectives were to improve the reclaim rates in order to more consistently deliver the right quality material to the loadout:

- 4.3% improved net reclaim rate

- 75% reduction in bucket wheel overtorque

This results in a more consistent production and quality mix to the loadout. The loadout itself was equipped with several iLoadout and iBelt modules for archiving:

- Train loading accuracy, allowing higher car set points without overloading

- 30% more train speed (from 0.9km/h to 1.2km/h)

- >1 ton less standard deviation (from 3.7t to 2.3t)

indurad was able to deliver the project at warp speed. It took 5 months and 2 days from order to acceptance.

Iron Ore Rollout Australia

indurad has partnered with a major iron ore company in Australia and has equipped 14 TLOs in Australia with the Autonomous Train Load Out System (ATLS). The rollout has been ongoing since 2012.

Depending on the site, the loadout is fed by an iReclaimer controlled iron ore stockyard and the bin above the railcar loadout is measured by an indurad iSilo solution. The loadouts are equipped with radar based speed measurement, ore car positioning systems and 2D radar chute automation.

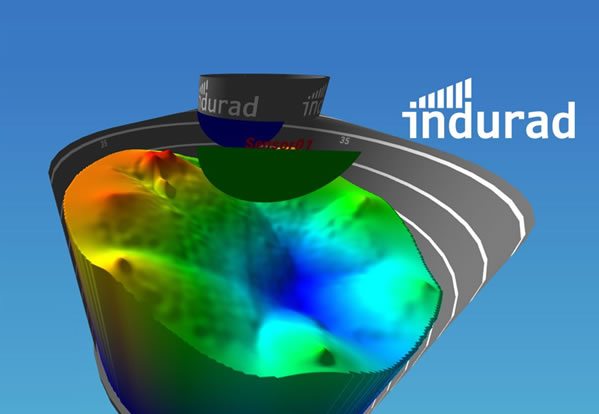

Lime Producer

Fast and easy installation

The compact iSilo solution, consisting of a single scanning radar (iSDR-P) and a combined processing and connectivity unit (iRPU-F) provides a complete surface model of the inventory.

Knowing the capacity and deriving the current fill level significantly improves loading and unloading and truck dispatch. The results are significantly reduced cue times and more customer deliveries per day. Especially one factor improves the overall dispatch process, as a loading truck does not have to wait any more until a unloading truck finished his work. So the system now allows simultaneous loading and discharging of the silo.

Aluminum Plant

Inventory information & Safety

The customer is an aluminum plant in Iceland. The material (alumina) they receive to feed the operation must be dispatched well in advance as it is delivered by vessels from distant suppliers around the globe.

The alumina is received into a large silo from which material is drawn into the operation. To maximize production, the silo should be close to empty when a ship arrives so that the maximum sized shipment can be received without halting production. To achieve this, precise knowledge of the volume of material in the silos is critical to make the optimal dispatching decisions in a long lead-time environment.

The customer also faced operational challenges when unloading the vessel as there was no information that could be used to adjust the silo’s 17 filling points individually. The material loaded into the silo was sometimes very unevenly distributed. To correct uneven loading, the operators could only slow the loading process to allow the material to slide down to a more even distribution. When the operators were able to see this effect during ship unloading, they were able to adjust different groups of filling points to make the filling more even. This ultimately allowed the customer to reduce unplanned and costly berth times.

Cement plant

Clinker Silo Greece

At our client site at a cement plant in Greece, knowing the exact fill level 24/7 is key to enable the plant manager to take the right decisions. The clinker silo acts as storage and buffer area between kiln and mill.

Thus, knowing both free capacity and remaining stock is important for a smooth management of upstream and downstream production. With the indurad iSilo solution, the client has this information available at all times. In addition, current dead stock in the silo is finally visible and thus can be taken into account to calculate current available capacity and to take corrective measures like wall cleaning. The indurad radar solution manages to scan where other technologies fail: high temperatures beyond 100°C, dusty environment, and moisture from the material. The sensor requires no regular cleaning or recalibration.

Tar & Oil Sands

In Canadian oil sands operations iBelt measures the material throughput at several critical points: Flow from bin to crusher, alarms for overflow, blockage, empty. Flow into mixboxes, thus reducing massively the amount of steam needed. Filling of intermediate hoppers. On continuous miners: material disposed into trucks / performance of mining machines and contractors.

Pulp & Paper

Measuring pulp and paper products with radar is a challenge. Due to indurad’s 77 GHz radar technology, our radar sensors are capable of measuring most wood products while e.g. dry cellulose is almost invisible to radar. Typical applications are: Canadian customers: To measure the volume flow of woodchips (inbound and outbound) for exact inventory information. European renewable power plant: Volumetric measurement data as a precondition for EU corporate sponsorship. Company delivers proof of compliance with EU legislation in the form of consumed material volume for eventual energy production.